Solution | Hot-Plug Mechanism Enables Rapid Modular Pallet Switching in Bus Welding Lines

As intelligent manufacturing and Industry 4.0 continue to evolve, bus welding lines are advancing into a new era characterized by higher automation, greater flexibility, and deeper informatization. Compared with passenger cars, bus manufacturing involves large structural components, low-volume and high-variety production, and frequent model changes, which impose higher demands on the flexibility of production lines and the scalability of control systems.

As one of the most complex and highly integrated processes in vehicle manufacturing, the automation level of welding lines directly affects production efficiency and product quality. As production lines expand and control precision improves, welding lines are becoming equipment-dense, tightly synchronized, and frequently cycled, which raises the bar for the reliability of signal connections and the efficiency of system maintenance.

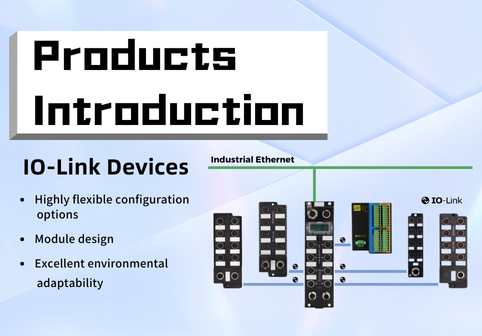

Against this backdrop, SENTINEL’s IO-Link product series—featuring highly flexible wiring capabilities and stable, reliable hot-plug mechanisms—is emerging as a key enabler in the intelligent upgrade of bus welding systems.

Increased Welding Complexity Poses I/O Wiring Challenges

Take a certain bus production line as an example: its welding workshop integrates various robotic stations, fixture switching systems, heavy-duty conveyors, and auxiliary information systems, forming a highly customized production line characterized by "multi-process linkage + multi-model switching + flexible scheduling." The production area spans over 3,680㎡ and includes 24 industrial robots, covering seven major system modules: arc welding, flipping, pallet transport, fixture change, automated dust removal, etc.

In such an environment, not only are the I/O points numerous, but they are also widely scattered across the line. Traditional centralized I/O wiring methods face challenges such as complex wiring, difficult debugging, and high maintenance costs. SENTINEL’s IO-Link solution, based on a master-and-distributed-substation architecture, effectively resolves issues of wiring redundancy and device access complexity, greatly enhancing deployment efficiency and response speed.

IO-Link Flexible Wiring Supports Long Conveyor Systems

Bus welding lines typically utilize flipping mechanisms, plate-chain conveyors, and upper-lower loop conveyors, which are long and expansive with control points scattered throughout. SENTINEL’s IO-Link substation modules can be deployed at each conveyor node, transmitting both signals and power through standard three-core cables—significantly simplifying wiring structures. The master station centrally manages all data and device statuses, enabling real-time local access and centralized diagnostics.

Additionally, SENTINEL products support IP67 protection, making them suitable for harsh environments such as welding dust, high temperatures, and oil contamination. They are also compatible with mainstream PLC platforms and industrial Ethernet, allowing seamless integration into existing automation systems to improve overall deployment efficiency and maintainability.

Hot-Plug Mechanism Enables Rapid Pallet Module Switching

Flexibility is another hallmark of bus welding lines. Especially in scenarios with mixed model production and frequent format changes, transport pallets—used to carry and move vehicle structures—must be replaced and debugged quickly. Traditional I/O connections often require powering down and disconnecting wires during pallet swaps, which is neither safe nor efficient.

SENTINEL IO-Link substations fully support hot-plugging, allowing users to replace modules or connect/disconnect pallets while the system remains powered. Each pallet is pre-integrated with a substation and sensors, requiring only a simple IO-Link connection. The system automatically identifies the device and uploads preset parameters—no manual intervention needed. This plug-and-play capability greatly facilitates modular unit construction and rapid line switching.

In complex scenarios like “automated fixture storage systems” and “flexible robotic welding systems,” the hot-plug feature of SENTINEL products ensures the system remains highly adjustable even under continuous operation.

Conclusion

IO-Link is not merely a field-level connectivity alternative—it forms the foundational infrastructure for intelligent bus manufacturing. SENTINEL IO-Link masters can coordinate with centralized information platforms, MES systems, and even edge computing devices to monitor and record real-time statuses of each substation and sensor group. Device data becomes fully transparent, diagnostics are traceable, and operational parameters can be remotely managed—creating a “data-driven, event-linked, rapidly responsive” smart O&M system.

Upgrading welding lines is not just about equipment replacement but architectural transformation. Faced with the bus manufacturing reality of “customization, multi-model, small-batch, high-frequency” production, SENTINEL’s IO-Link series empowers welding lines with enhanced adaptability and sustainable scalability through flexible wiring, hot-plug support, data visualization, and modular design.

Looking ahead, SENTINEL will continue to deepen its focus on industrial communication and field connectivity technologies, providing advanced and reliable technical support to bus manufacturers striving for high-quality, intelligent development.

Customer Support and Services

To learn more about SENTINEL’s products, please contact our sales staff or call 022-83726972. You can also visit our official website at www.sentinel-china.com. The website provides comprehensive product details, selection guides, CAD and Eplan files, as well as configuration documents and tutorials—ensuring users can easily find what they need.

Our professional technical team is always ready to provide customized customer support and efficient after-sales service to maximize the value for every user.