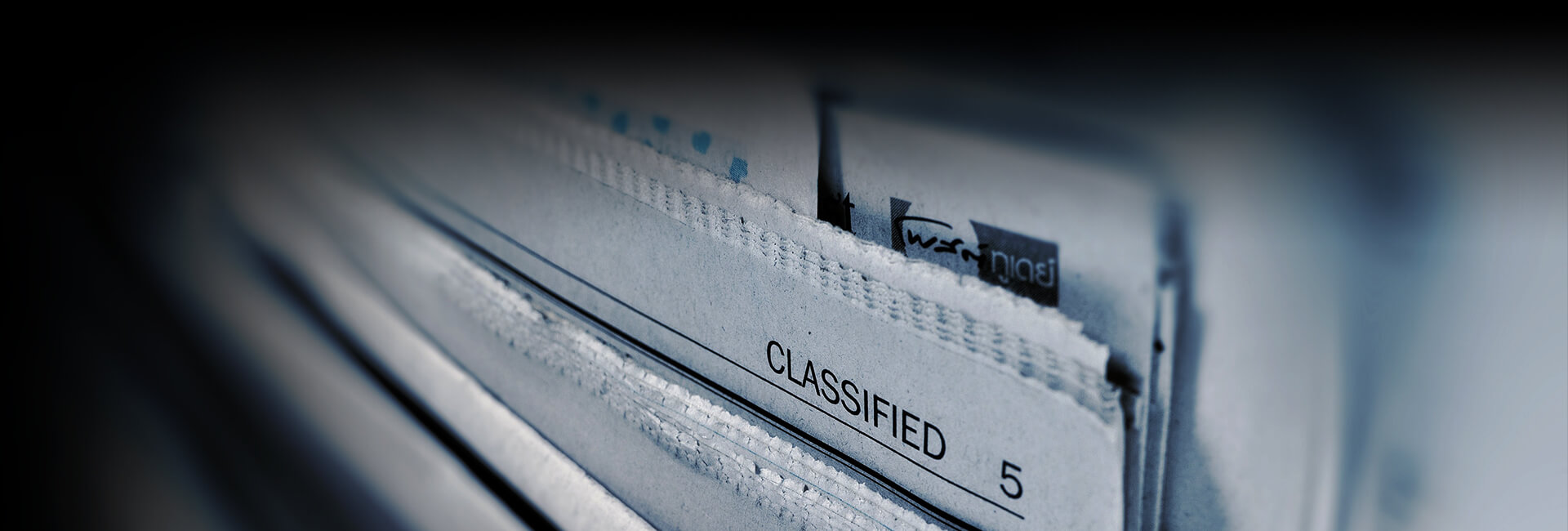

New Product Launch | I/O Adaptive and Scalable IO-Link Slave Modules Officially Released!

These two modules offer both Class A and Class B interface versions to meet the diverse needs for interface power and power isolation across different industries and application scenarios. They bring unprecedented flexibility and convenience to field device connectivity and system integration.

Intelligent Adaptation, Stable & Efficient — I/O Adaptive IO-Link Slave Module

This module features automatic port detection that identifies whether the connected device is for input or output and dynamically switches the process data accordingly — with no additional parameter settings needed, achieving true "plug-and-play". The module supports 16 channels of digital input/output, with a fixed 2-byte process data per channel, ensuring high-quality, stable communication.

The Class A version (SIOL-M12A-16SAP) is suitable for shared power source scenarios, while the Class B version (SIOL-M12B-16SAP) provides independent pins for load power, ideal for high-power applications. It supports IO-Link COM2 communication speed (38.4 kbit/s), IP67 protection, and wide temperature operation (-20°C to +55°C), making it suitable for harsh environments.

Flexible Expansion, Freely Configurable — I/O Adaptive and Scalable IO-Link Slave Module

As an extension of the base slave module, the scalable version supports module-level cascading to enable complex automation networks with multiple layers and devices. Each module has two IO-Link ports: one for primary communication and the other for expansion, enabling seamless daisy-chained communication.

The total process data of the module is fixed at 6 bytes for input and 4 bytes for output, regardless of whether it’s connected to expansion modules, improving system predictability. Each expansion slave module port supports 2 bytes of input and 2 bytes of output process data, avoiding waste of system resources.

Moreover, the module is equipped with overload and overheating protection mechanisms, further enhancing system stability and on-site safety.

Broad Application Prospects, Empowering Digital Transformation

With the official launch of these two modules, users can flexibly address production line adjustments and device integration needs without replacing the main system, significantly reducing transformation costs while improving compatibility and maintainability. (With the scalable slave module, one IO-Link master can connect to 16 slave modules with 16 channels each, managing up to 256 I/O points.)

Whether in automotive manufacturing, smart logistics, or food and beverage processing, these IO-Link slave modules are set to become a critical foundation for achieving efficient collaboration and intelligent sensing.

Act Now, Get Support

SENTINEL has published product selection guides, CAD drawings, Eplan files, and configuration manuals on its official website. Visit www.sentinel-china.com for complete product information, or contact a sales representative or call the service hotline at 022-83726972 for detailed consultation.

Our experienced technical team is ready to provide personalized selection advice, deployment guidance, and after-sales support to help you quickly and efficiently implement your project.