New Product Launch | Class A and Class B Devices

Since the launch of IO-Link products, Sentinel has gained widespread recognition in the industry through continuous iteration and innovation, driven by customer needs. With the joint efforts of our R&D team, the Sentinel IO-Link product family has been expanding. Today, we will continue to introduce two types of products to you: IO-Link Analog Devices and IO-Link Class B Interface Devices.

Product Introduction

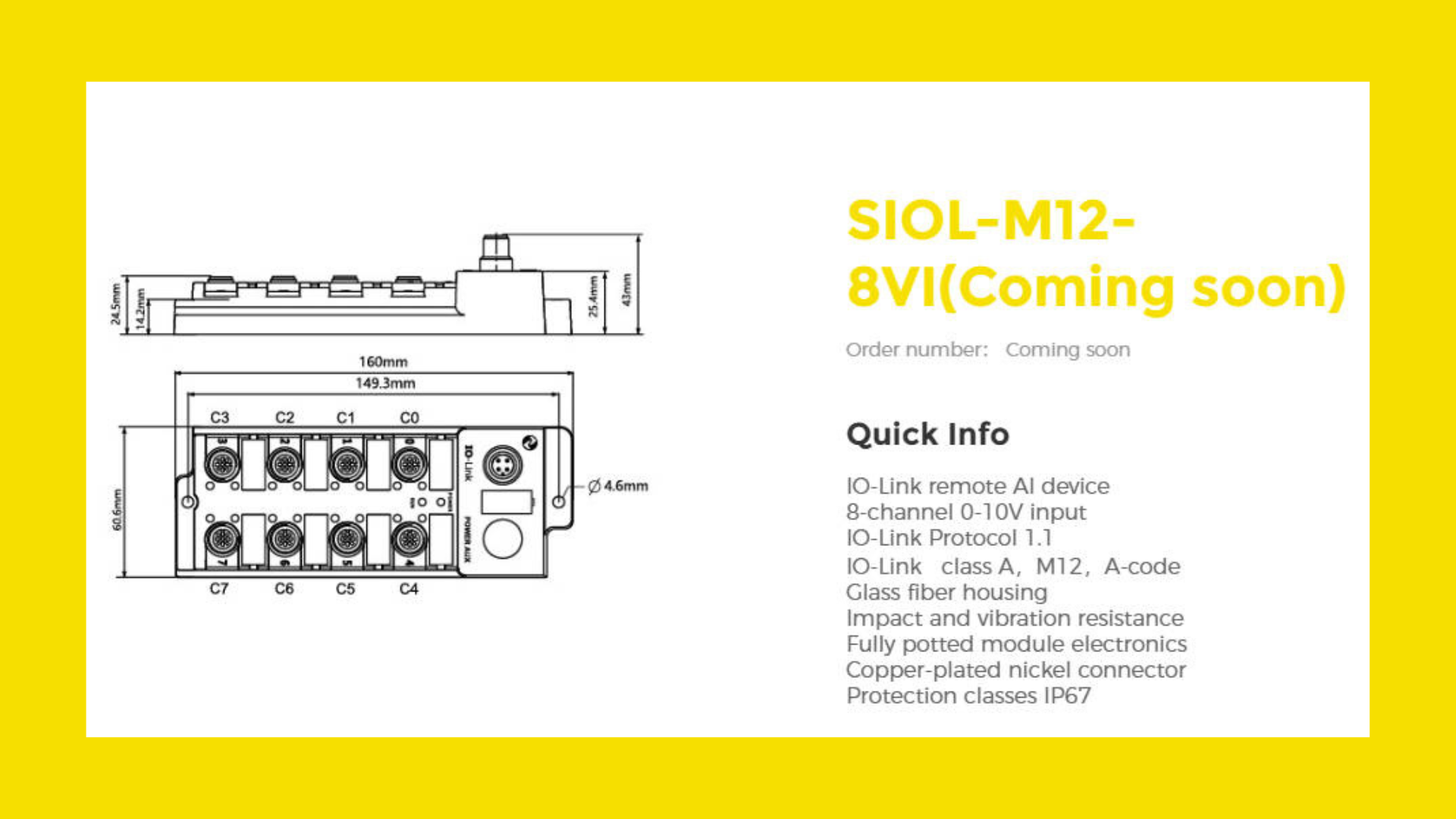

IO-Link Analog Devices

The IO-Link Analog Devices (SIOL-M12-8AI/SIOL-M12-8VI) comply with the IO-Link V1.1 protocol, ensuring seamless connection with IO-Link master devices. With a maximum data transmission rate of up to 230.4kbit/s, these Devices ensure rapid and accurate data transmission, making them an ideal choice for industrial field data collection.

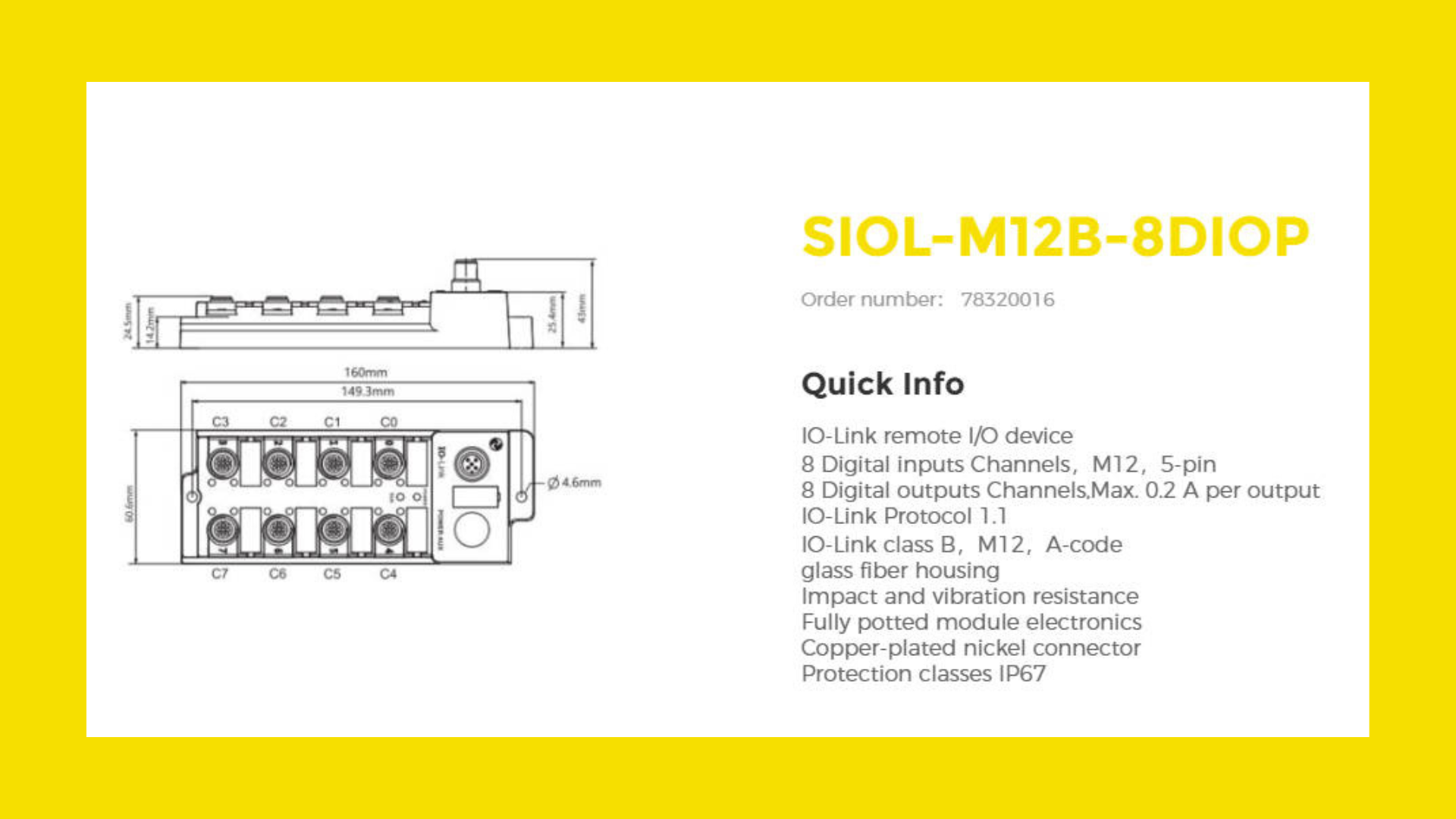

IO-Link Class B Interface Devices

The IO-Link Class B Interface Devices (SIOL-M12B-8DIOP/SIOL-M12B-16DO) also comply with the IO-Link V1.1 protocol. The Class B interface can power loads without additional cables, making wiring more straightforward. It ensures stable energy and data transmission, maintaining efficient operation even in situations of high power consumption or longer cable lengths.

Market and Customers

The photovoltaic, new energy, and intelligent logistics sorting industries have extremely high requirements for the speed, accuracy, and flexibility of automation systems. The production and logistics processes in these industries often involve the real-time processing of large amounts of data and rapid communication between devices.

Using IO-Link series devices with faster transmission speeds brings multiple advantages:

- Improved System Response Speed: The rapid data transmission capability means the system can respond more quickly to changes, such as adjusting the angle of photovoltaic panels, responding to load changes in energy management systems, or executing sorting instructions quickly in logistics sorting.

- Enhanced Data Accuracy: High-speed transmission reduces communication delays, which is crucial for ensuring the real-time nature and accuracy of data. In the photovoltaic and new energy industries, this may involve real-time monitoring of system performance and output, while in logistics sorting, it can ensure immediate updates of tracking information.

- Better System Integration: IO-Link devices provide standardized interfaces and communication protocols, meaning they can be easily integrated into existing industrial automation environments, reducing the complexity and cost of integration.

- Intelligent Device Management: IO-Link technology supports remote configuration and monitoring, making device management more intelligent. This is particularly important for remote monitoring of the status of photovoltaic systems, performance of new energy equipment, and maintenance of logistics automation equipment.

- Simplified Wiring Requirements: Compared to traditional distributed I/O bus modules, IO-Link devices can connect through standardized three-wire cables, reducing wiring costs and complexity.

- Diagnostic and Predictive Maintenance: IO-Link devices often have advanced diagnostic functions that provide detailed information about device status and performance, facilitating predictive maintenance and reducing downtime.

- Cost-Effectiveness: As IO-Link devices can utilize existing sensors and actuators, they reduce the need for specialized hardware and can offer upgrades and improvements without the need for extensive replacement of existing equipment.

Customer Support and Services

If you want to learn more about IO-Link master and slave products, please contact our sales staff or call the company. We have a professional technical team, ready to provide customized customer support and efficient after-sales service, ensuring the best interests of every user.