China's Intelligent Manufacturing: The Application of SENTINEL Products in the Bearing Industry

Seeking an automation control solution

Let me introduce myself. I am an electrical engineer from the bearing industry in Ningxia. We need remote I/O modules for the logistics and transportation equipment between the inner and outer ring machine tools for processing bearings. At that time, we were looking for an economical and reliable solution for automation control. During the initial selection process, we considered that domestic brands have already achieved a certain level of maturity in this type of module technology. After comprehensive consideration, we decided to use a domestic brand.

Choose SENTINEL products.

We logged in to the official website of SENTINEL China (www.sentinel-china.com) to learn about their products. Through subsequent communication with the sales and technical team, we discovered that they had a deep understanding of IO-Link communication technology. After explaining our requirements in detail, they provided us with the most cost-effective and reliable solution. Compared to solutions offered by some well-known foreign brands, the cost was significantly reduced. This customer-oriented approach in problem-solving and providing solutions has instilled in us a great deal of trust in SENTINEL. As a result, we have decided to choose SENTINEL products.

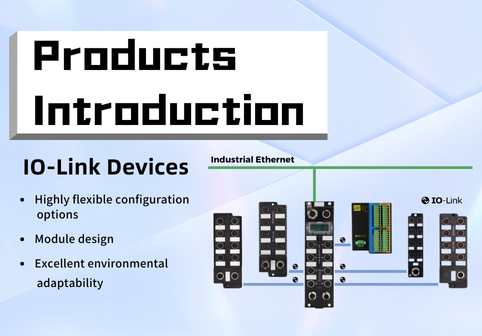

We used two EL series main stations from SENTINEL, communicating with Siemens PLC through PROFINET protocol. The main stations are connected to 12 sub-stations (including 16 inputs and 16 outputs). Input devices are connected to sensors, buttons, magnetic switches, etc., on the conveyor line, while output signals primarily control solenoid valves and indicator lights.

Rich and convenient official website resources

However, there are always some small problems when using a new product for the first time, such as device connection abnormalities. By observing the indicator lights, the cause can be identified, but the position of the indicator lights is relatively concealed, making it difficult to detect during initial use. After watching the video tutorials on the official website, I learned about the corresponding operating status of the indicator lights, thereby solving the problem. In addition, the "Video Center" also provides various examples of module connections, with clear explanations, making it easier to understand after viewing; at the same time, we also discovered that the SENTINEL official website has a comprehensive product details and data download section, such as the "Download Center" which provides various materials for download, such as CAD files and EPLAN component macros, improving the efficiency of my drawing work. The website's style and the completeness of the information provided have given me a very good experience.

Professional responsible after-sales service

In terms of communication, response speed, and problem-solving, SENTINEL's performance is impressive. There was one instance on-site where frequent disconnections occurred during the night and resolved on their own. When I arrived on-site, I didn't know where to start, so I contacted the technical department. I thought it was too late and they wouldn't reply, but Li quickly responded and assisted me in quickly identifying the problem. The reason was that the electrician didn't properly connect one of the network interface connectors. Such quick handling and response received positive feedback from the on-site client regarding our service and attitude, which played a significant role in generating the second order.

Summary and Suggestions

On the other hand, I have summarized some experiences in terms of product usage, hoping to provide effective improvement suggestions for SENTINEL's products. For example, both the auxiliary power interface and the IO-Link communication interface of the output substation module have M12 four-pin male connectors, which are easy to be plugged in incorrectly. In addition, the yellow silk screen on the master station module is not very clear, which affects the appearance quality of the product. As for the port and cable identification, we hope to provide some alternative solutions to assist customers. The labels printed by the marking machine are not very aesthetically pleasing when they are applied, which affects the appearance of our products. On the other hand, we hope SENTINEL can launch an 8-channel module with arbitrary configuration of inputs and outputs, making it more flexible to use.

The solution provided by SENTINEL has significantly improved our efficiency and reduced costs. We are very satisfied with this. I hope that SENTINEL can further expand the influence of the national brand, making more people aware of and use SENTINEL's products. I believe this will also bring more possibilities for our cooperation.