IO-Link Hub Upgrade

Loading...

2023-07-05

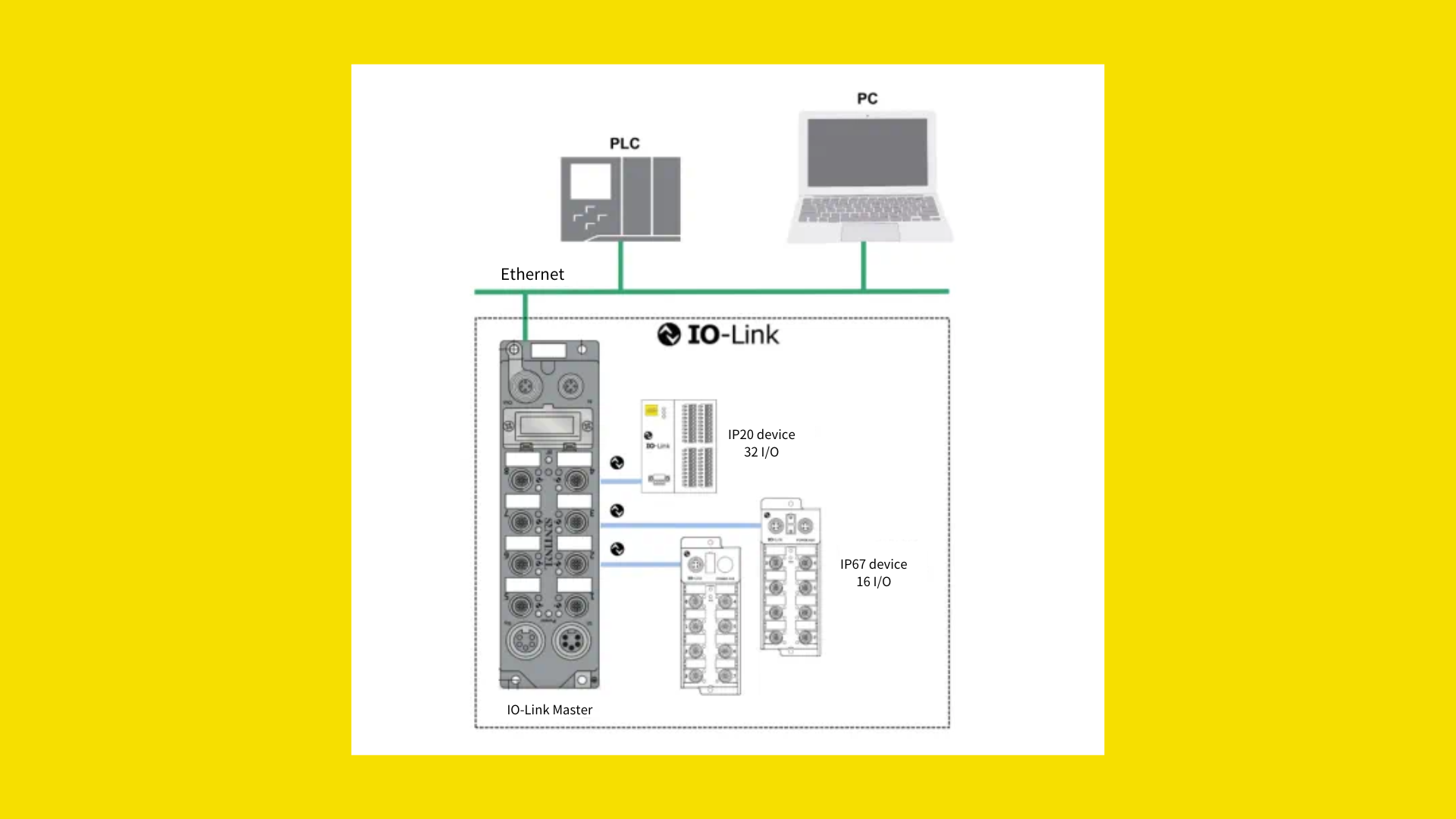

In the previous article, "IO-Link Makes Sensors Smarter," we introduced the application of IO-Link in "smart devices" and talked about many advantages of IO-Link in the "smart devices" field. In this article, we will explain how IO-Link makes "processing traditional digital signals" more efficient.

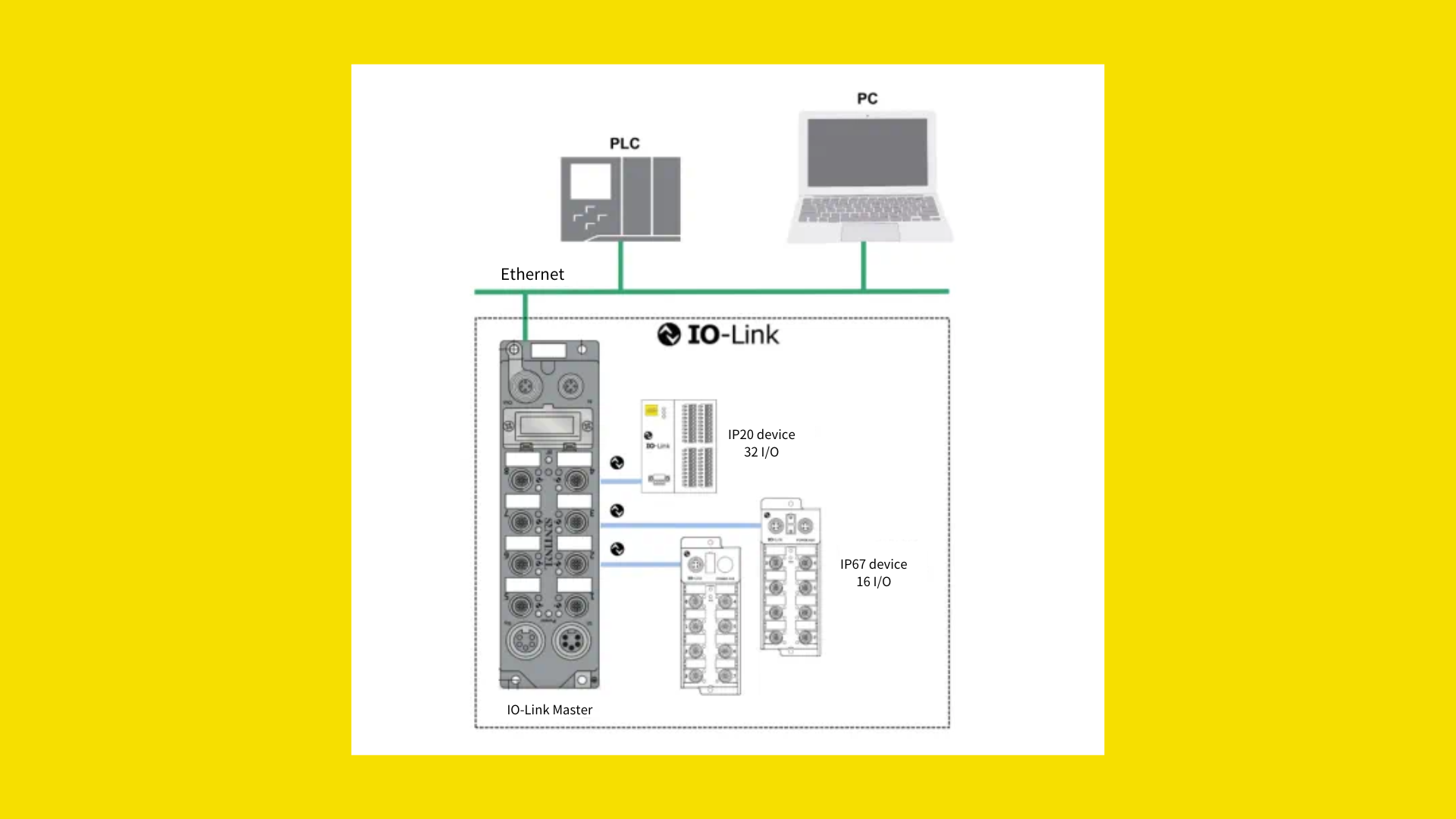

Positioning of an IO-Link Hub

IO-Link hubs are an extension of the master station. Each IO-Link port of the master station can be connected to a hub, and each hub can process up to 32 digital signals. You can connect the hubs in a star topology to the master station, allowing the master station to process up to 256 digital signals.

Advantages of IO-Link Hub

1. Simplify the wiring to enhance efficiency

Traditional wiring methods require a large amount of signal wires to connect sensors and actuators with PLCs, while using an IO-Link hub can be installed near the sensors and actuators, saving a lot of signal cables. Only one three-core unshielded cable is needed to connect with the main control cabinet. Wiring is more convenient and efficient.

2. Flexible installation, strong compatibility

The IO-Link hub is small in size and has an IP67 protection level, making it suitable for on-site installation. The hub with an IP20 protection level has a bottom DIN35 rail clip, making it suitable for nearby installation in the control cabinet. It follows the IO-Link v1.1 standard and specification, using the IO-Link CLASS A interface, compatible with any brand of IO-Link master station.

3. Diagnosis feedback, convenient for maintenance

The IO-Link hub has independent power supply and configuration, built-in short-circuit and overload protection, and provides alarm function. Users can realize online parameter configuration of the IO-Link hub through corresponding software. They can also use the online diagnosis function of the PLC to view relevant alarm information in real time, making it more convenient for both early debugging and later maintenance.

Application of IO-Link Hub

Taking our company's IO-Link products as an example, we will introduce two applications:

1. On-site installation

IP67 protection level, the maximum distance between the master station and the substation can reach 20 meters. The sub-stations are distributed in a star shape, centered around the master station and connected by a common 3-core cable. The coverage area is wide and installation is more convenient with the fast-connecting plug-in.

click the image to open products website

2. Cabinet Installation

IP20 protection level, metal casing, bottom DIN35 rail, installed in the control cabinet near the sensor/actuator, also uses ordinary three-core cable to connect to the main station of the main cabinet (such as Siemens 6ES72784BD320XB0, 6ES71376BD000BA0, etc.). Compared to traditional wiring, it is indeed much more convenient.

click the image to open products website

Summary

As an enterprise specializing in the automation control field, SENTINEL actively promotes the use of the IO-LINK digital communication protocol and provides IO-LINK master station modules that support multiple bus protocols and diverse IO-LINK sub-devices. They can be widely applied to industries such as solar power generation, warehousing and logistics, automobile manufacturing, 3C electronics, and battery swapping stations. These products and solutions can provide customers with a reliable and low-cost transmission method, realizing low-cost and high-efficiency productivity from sensors to controllers.